Sistema avanzado de inspección de alimentos XSpectra

Sistema avanzado de inspección de alimentos XSpectra

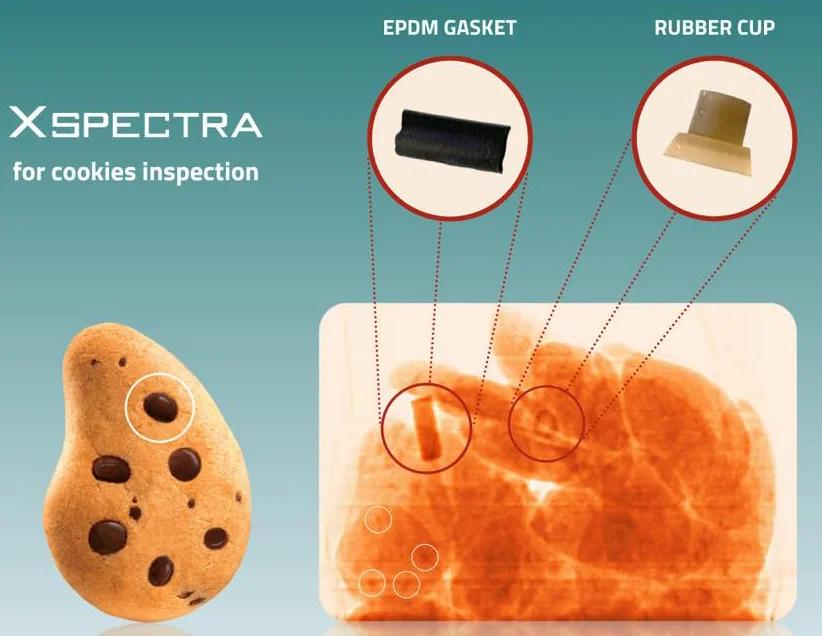

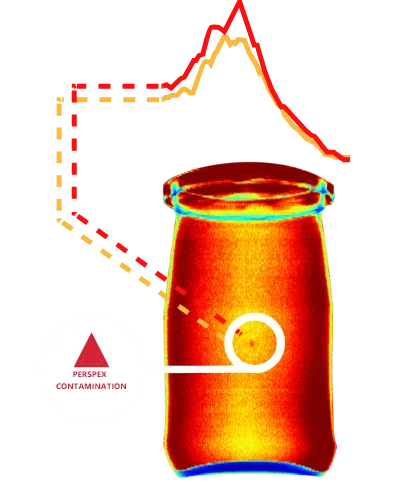

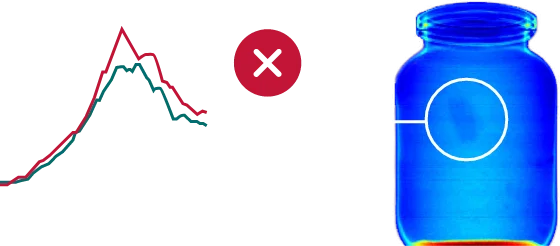

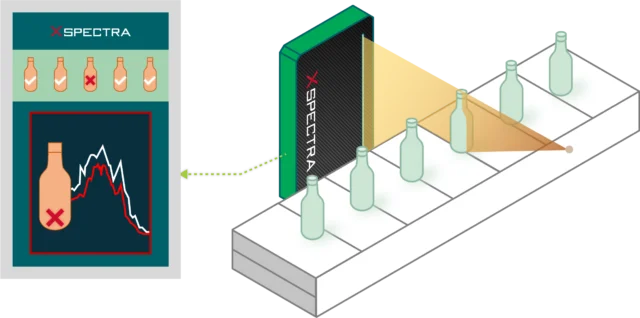

XSpectra® es una tecnología innovadora, el primer sistema de inspección hiperespectral de la industria alimentaria basado en la técnica de photon counting, capaz de realizar análisis químicos y físicos del producto en tiempo real para identificar cuerpos extraños actualmente indetectables mediante las tecnologías de inspección existentes.

It performs a spectral analysis, comparing up to 1.024 energy levels the different absorption of the product with respect to the contaminant.

In a few milliseconds, it performs a chemical-physical analysis of each product on the processing line.

A revolutionary inspection system that detects low-density foreign bodies all along the processing line:

- Metal

- Stone

- Glass

- Nuts

- Bones

- Wood

- Plastics

on bulk or packaged products.

Benefits

- Increasing food safety and quality

- Supporting food waste reduction

- Fighting counterfeiting and fraud

- Providing a cost-effective approach

- Facilitating the production process and logistics

- Increased focus on consumer protection

- Preserving corporate reputation