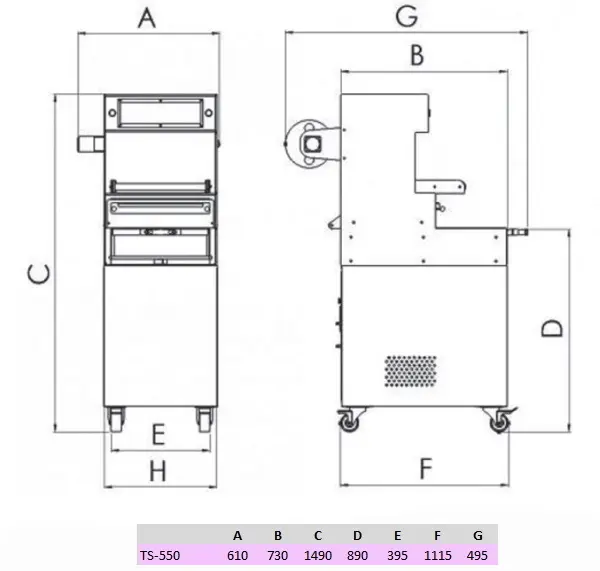

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550

Food thermo-sealing is a method of closing trays by applying pressure and heat to a plastic film using a manual, semi-automatic or automatic tray sealer such as those produced by AK RAMON. It is also known as heat sealing and serves to isolate the products stored in the container from air and other external agents such as bacteria and microbes. The main characteristics of a good manual tray sealer are that it can be adapted to all types of heat sealable containers and guarantees rapid heating of the Teflon plate thanks to a power that must be at least 900 W to reach 230º C. There are many advantages to using heat sealing for food preservation: It offers a more attractive and hygienic presentation of the food for the consumer. Heat-sealing allows food to be kept in excellent condition, preventing it from being crushed. The use of heat-sealing facilitates the storage of food in suitable plastic containers or heat-sealable trays.

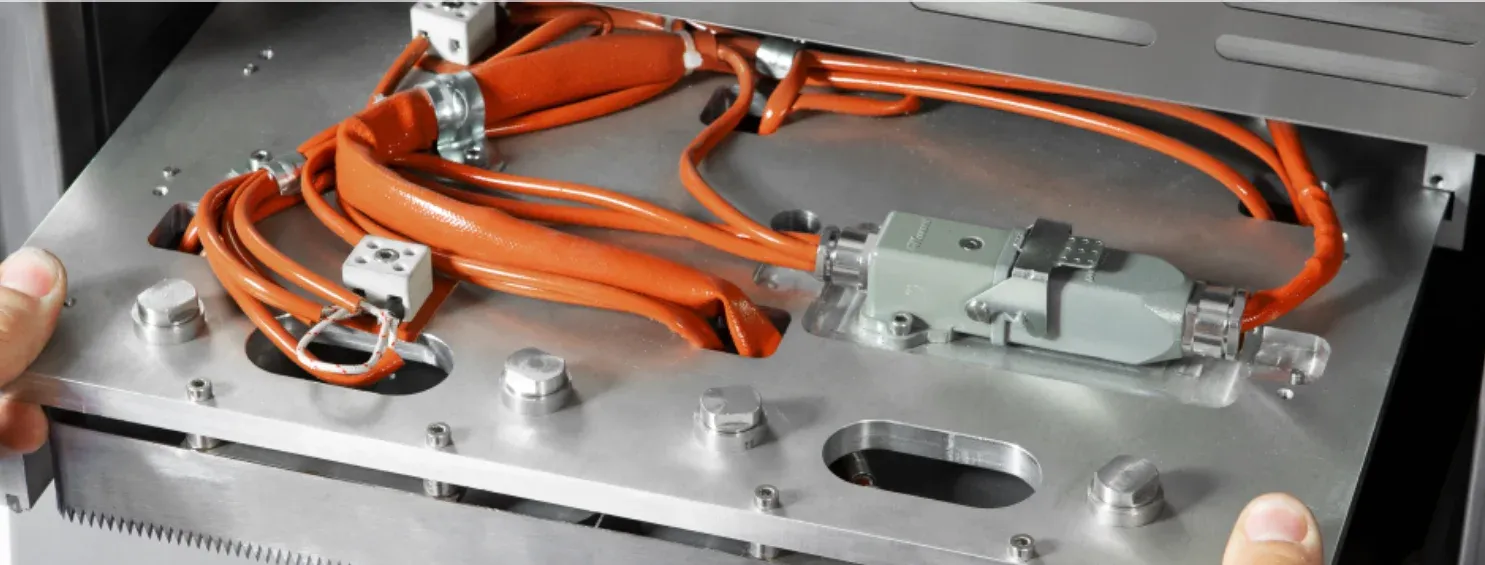

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550 fast heating of the selected temperature, manufactured in stainless-steel AISI 304, die sets in anodized aluminum. Perfect for transporting food without loss of liquids or sauces. Compact and robust model equipped with gas flushing, digital control panel, easy change of molds that are interchangeable in a few seconds, gas flushing entrance and vacuum control by sensor, sealing temperature and time regulation. It allows working with different types of tray materials, PP, PET, Aluminum, etc. Maximum sealing surface 320×260 mm, film roll width 400 mm, power 1500 W.

TRAY SEALER TS-550 has VAC-STOP push button, finish the vacuum & continue the process, maintenance push button control, digital panel equipped with 99 memory programs, monitoring step-by-step of the cycle through LEDs and pump capacity 25 m³/h.

Standard molds with perimeter film cutting:

1/2 GN (320×260 mm) — 1 tray.

1/4 GN (260×160 mm) — 2 trays.

1/8 GN (168×130 mm) — 4 trays.

Standard molds with film cut at the back, non-perimeter:

1/2 GN (320×260 mm) — 1 tray.

1/4 GN (260×160 mm) — 2 trays.

1/8 GN (168×130 mm) — 4 trays.

Any type and shape of mold can be manufactured according to the customer trays.

Features

- Digital control panel.

- Vacuum control by sensor.

- Gas flushing entrance control by sensor.

- Sealing time regulation.

- Soft-air.

- VAC-STOP push button, finish the vacuum & continue the process.

- Maintenance push button control.

- 99 memory positions.

- Monitoring step by step of the cycle through led.