Stainless Steel Buggies Washer MMK 20

Stainless Steel Buggies Washer MMK 20

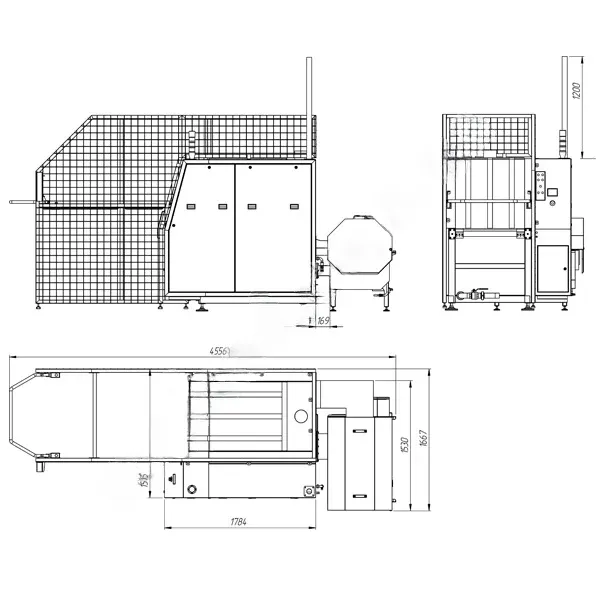

KOMPO MMK-20 is an industrial washing machine designed for automatic cleaning of standard 200-liter minced meat carts used in food processing plants in Canada and the USA. Using a high pressure washing system, the machine effectively removes all grease, protein residue and other food contaminants, ensuring full compliance with the strict sanitary standards of the food industry in the United States and Canada. Constructed of stainless steel, the MMK-20 is extremely durable, easy to maintain and low maintenance, making it an indispensable cleaning solution for meat processing plants, abattoirs and food processing plants.

At KOMPO North America Inc. you will find a wide range of washers and hygienic stations for businesses in Canada and the USA. Our catalogue also includes a wide range of equipment for meat, dairy, bakery, pet food and other industries. As well as high quality consumables for sausage producers and others who need clips, casings, loops, shrink bags and much more.

Loading:

The operator installs the container in the loading device (located on the door of the machine), after which the container is automatically loaded into the cabin.

Washing:

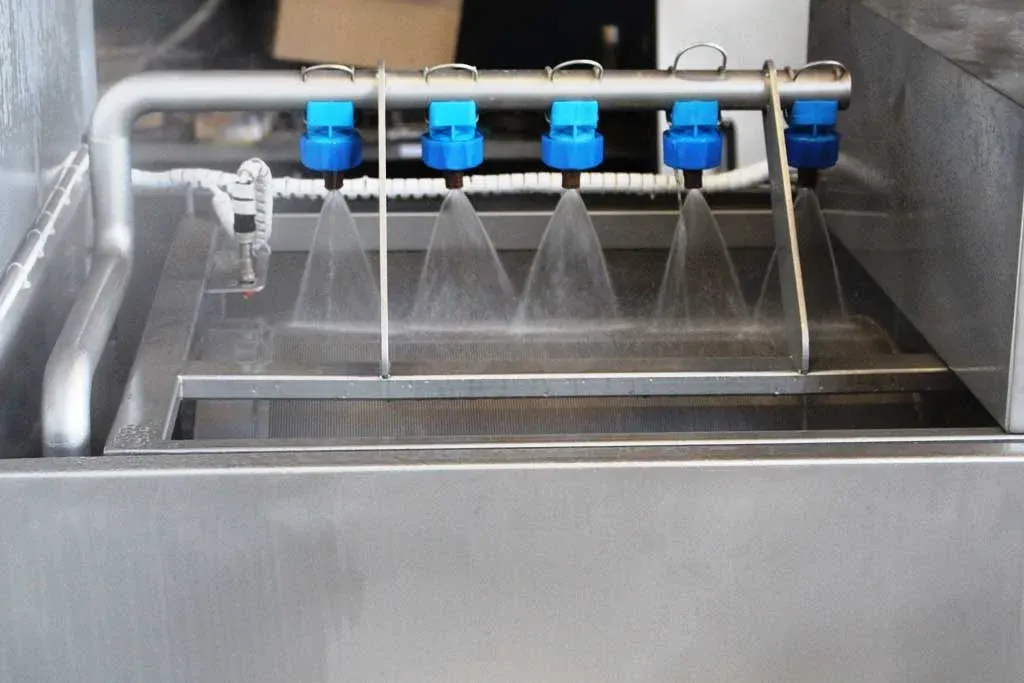

Washing takes place with warm water at a temperature of up to + 60C (depends on the temperature of the incoming water and the environment) with the addition of detergent. The tank of the machine receives water with a temperature of at least + 40C. Under the action of heating elements or steam, the set temperature of the cleaning solution is maintained. Also, detergent is automatically supplied to the tank (a non-saturated alkaline detergent is used). After that, the heated cleaning solution is fed by means of a centrifugal pump into the washing frame, which performs a rotational movement, where water under pressure washes the surfaces of the container with the help of nozzles. The spent cleaning solution flows through the filter back into the tank, carrying away the contamination. Dirt from the filter is removed by the operator (a rotary filter can optionally be installed to automate the drum cleaning process). The water level in the tank is maintained automatically.

Rinsing:

Rinsing takes place with mains water without additional pumps. Water washes the container through a rinsing frame equipped with nozzles. The frame performs movements similar to the frame of the sink. The wastewater replenishes the tank of the main sink. It is also possible to set up the drainage of water after rinsing directly into the sewer.

Discharge:

After the washing and rinsing process is completed, the door opens and the operator removes the washed container.

All KOMPO machines are designed and manufactured in Europe with European, Japanese, and North American parts – efficient, reliable, long warranty!

The design features:

- Automatic maintenance of the cleaning solution level within the tank.

- Incorporation of a cleaning solution filtration system enabling the reuse of the solution.

- Implementation of digital temperature control for precise regulation of the cleaning solution’s temperature.

These features collectively ensure efficient and sustainable operation, maintaining optimal solution levels, allowing for solution reuse, and offering precise temperature control for effective cleaning processes.