TERMOSELLADORA AUTOMATICA CON VACIO Y GAS TS-550

TERMOSELLADORA AUTOMATICA CON VACIO Y GAS TS-550

El termosellado de alimentos es un método de cierre de barquetas aplicando presión y calor a un film de plástico por medio de una termoselladora manual para barquetas, semi-automática o automática como las que producimos AK RAMON. También se conoce como sellado térmico y sirve para aislar los productos almacenados en el contenedor del aire y otros agentes externos como bacterias y microbios. Las características principales de una buena termoselladora manual para barquetas son que pueden ser adaptables a toda clase de envases termosellables y garantizar un rápido calentamiento de la placa teflonada gracias a una potencia que debe ser mínimo de 900 W para alcanzar 230 °C. Son muchas las ventajas de utilizar el termosellado para la conservación de alimentos: Ofrece una presentación más atractiva e higiénica de los alimentos para el consumidor.

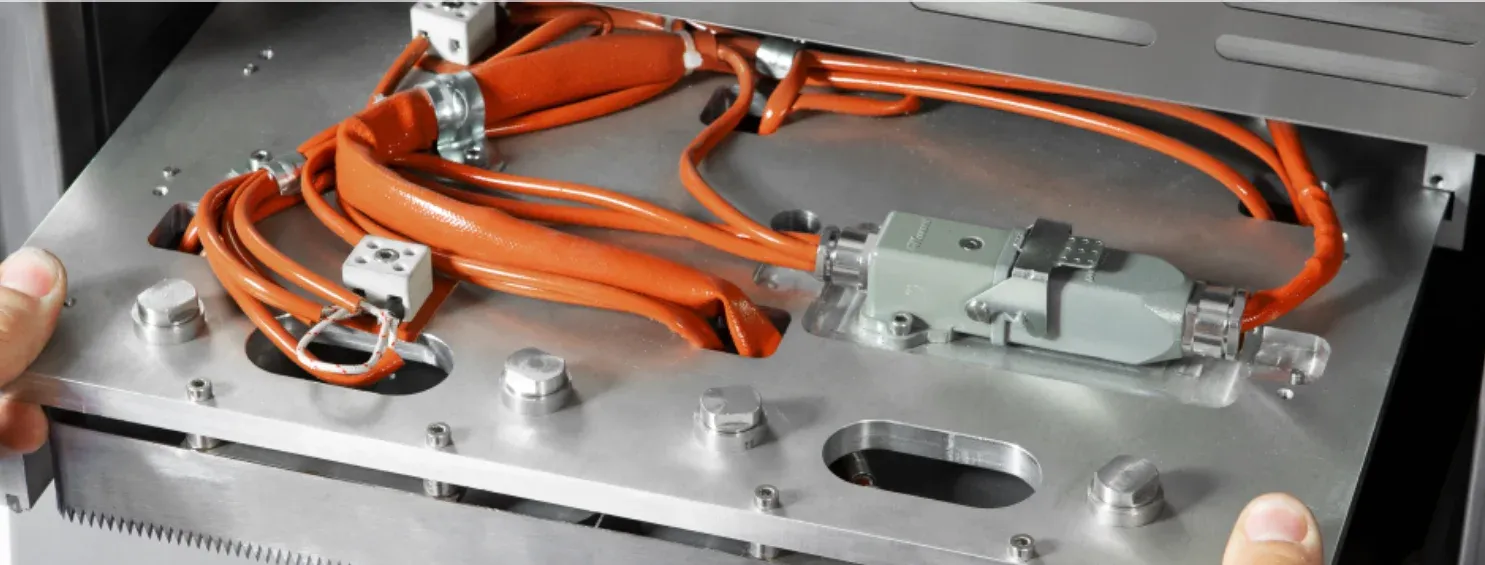

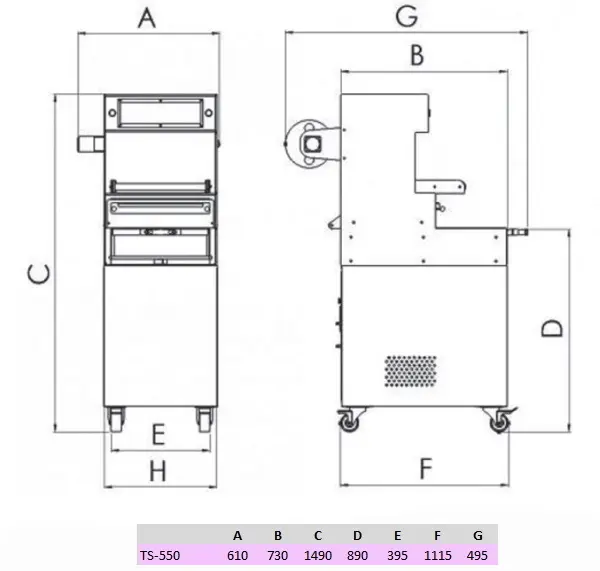

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS TS-550 fast heating of the selected temperature, manufactured in stainless-steel AISI 304, die sets in anodized aluminum. Perfect for transporting food without loss of liquids or sauces. Compact and robust model equipped with gas flushing, digital control panel, easy change of molds that are interchangeable in a few seconds, gas flushing entrance and vacuum control by sensor, sealing temperature and time regulation. It allows working with different types of tray materials, PP, PET, Aluminum, etc. Maximum sealing surface 320×260 mm, film roll width 400 mm, power 1500 W.

TRAY SEALER TS-550 has VAC-STOP push button, finish the vacuum & continue the process, maintenance push button control, digital panel equipped with 99 memory programs, monitoring step-by-step of the cycle through LEDs and pump capacity 25 m³/h.

Standard molds with perimeter film cutting:

1/2 GN (320×260 mm) — 1 tray.

1/4 GN (260×160 mm) — 2 trays.

1/8 GN (168×130 mm) — 4 trays.

Standard molds with film cut at the back, non-perimeter:

1/2 GN (320×260 mm) — 1 tray.

1/4 GN (260×160 mm) — 2 trays.

1/8 GN (168×130 mm) — 4 trays.

Any type and shape of mold can be manufactured according to the customer trays.

Features

- Digital control panel.

- Vacuum control by sensor.

- Gas flushing entrance control by sensor.

- Sealing time regulation.

- Soft-air.

- VAC-STOP push button, finish the vacuum & continue the process.

- Maintenance push button control.

- 99 memory positions.

- Monitoring step by step of the cycle through led.