BOX WASHING MACHINE MMY 1200

BOX WASHING MACHINE MMY 1200

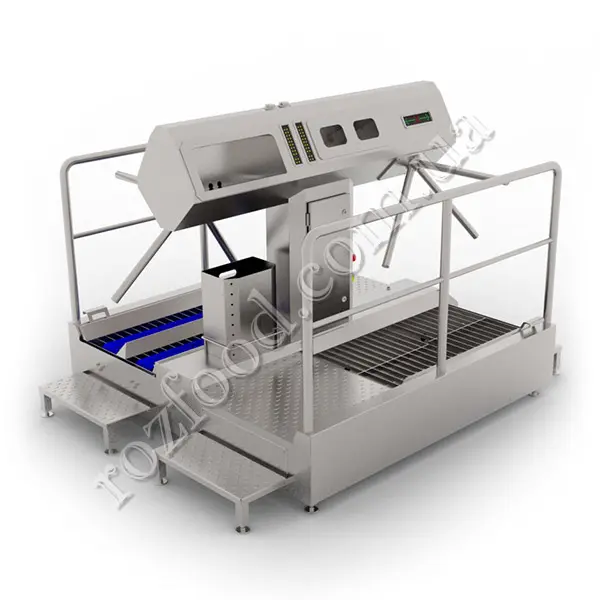

KOMPO MMY-1200 Box Washing Machine is engineered for industrial-scale cleaning of plastic crates, meat boxes, and other reusable containers. Designed for high-capacity food production environments, it delivers exceptional washing performance while meeting strict hygiene standards. Constructed from heavy-duty stainless steel and equipped with powerful nozzles, the MMY-1200 efficiently removes grease, protein, and other contaminants. Its robust design, low operating costs, and user-friendly operation make it an essential asset for processing plants and distribution centers across North America.

At KOMPO North America Inc. you will find a wide range of washers and hygienic stations for businesses in Canada and the USA. Our catalogue also includes a wide range of equipment for meat, dairy, bakery, pet food and other industries. As well as high quality consumables for sausage producers and others who need clips, casings, loops, shrink bags and much more.

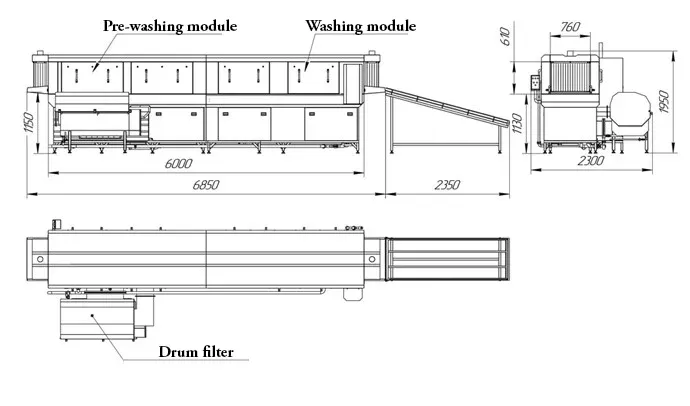

The washing machine works at temperatures up to 65°C, significantly enhancing the quality of cleaning containers. The water is heated, and its level is automatically maintained in the pre-washing tank. It continually recirculates, passing through the drum filter.

Within the washing module, containers are cleaned using a solution heated to a maximum temperature of 65°C. The preparation of the solution (heating and addition of cleaning agents) occurs within the machine’s tank. The temperature and concentration of the solution are automatically sustained throughout the washing process. Electric heating elements facilitate the heating process. The solution is applied to the container’s surface via a system of high-pressure nozzles connected through collectors.

The design features of the machine include:

- Versatility adaptable to various container dimensions.

- Manufactured using stainless steel AISI 304.

- Conveyor speed adjustment capability (additional function).

- Automatic maintenance of the cleaning solution level in the tank.

- Filtration system for the cleaning solution, allowing reuse.

- Automatic maintenance of the cleaning solution’s temperature.

- Digital temperature control for precise adjustments of the cleaning solution.

- Automatic maintenance of the cleaning solution concentration (additional function).

- Water recirculation system.

TYPES OF PROCESSED CONTAINERS

- plastic boxes (calibrated, warehouse, for freezing, universal)

- plastic universal containers (automotive standard)

- euro containers

- bottles finpack

- meat boxes (meat, sausage, fish, poultry, for freezing)

- boxes for dairy products

- bread, confectionery boxes

- yeast boxes

- boxes for bottles

- boxes for vegetables

- boxes for flowers, seedlings.