Boxes Tunnel Washer MMY 600

Boxes Tunnel Washer MMY 600

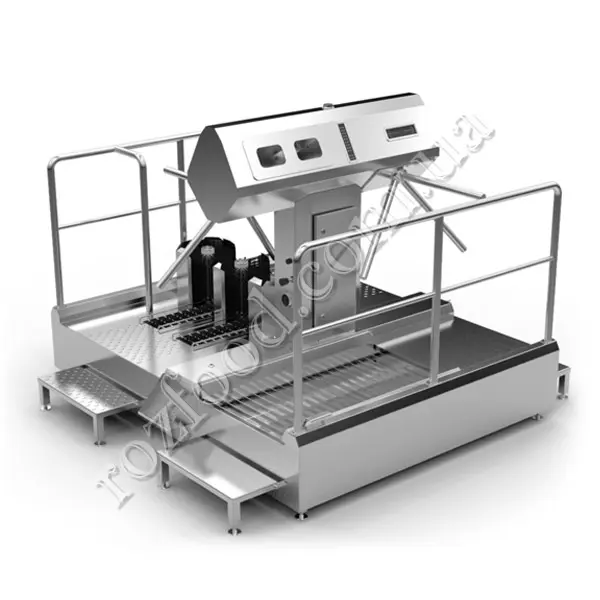

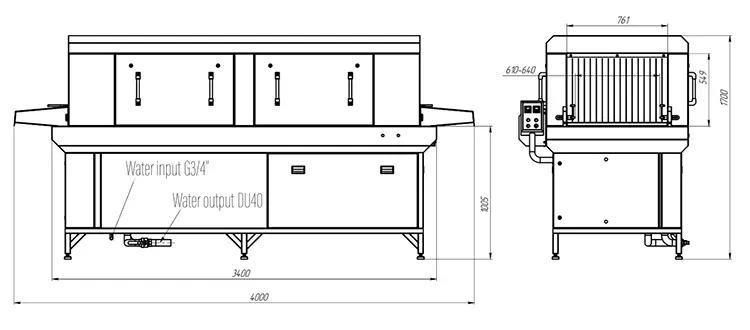

KOMPO MMY-600 tunnel washer is a compact but uniquely efficient crate and container cleaning system, designed for food processing plants in the USA and Canada, where high standards of hygiene are required. Thanks to its modular design and optimized water flow in the tunnel , this industrial washing machine ensures thorough sanitation of plastic crates, containers and trays even in high volume applications. Model MMY-600 is made entirely of corrosion-resistant stainless steel and features advanced water recirculation and filtration systems to minimize operating costs and maximize cleaning efficiency.

At KOMPO North America Inc. you will find a wide range of washers and hygienic stations for businesses in Canada and the USA. Our catalogue also includes a wide range of equipment for meat, dairy, bakery, pet food and other industries. As well as high quality consumables for sausage producers and others who need clips, casings, loops, shrink bags and much more.

Tunnel-type box washing machine MMY 600 is a versatile industrial washer designed to clean industrial boxes of E1, E2, and E3 types. It can also be adapted to wash bread trays, plastic trays, or boxes for transporting live birds. Containers to be washed are conveyed through the tunnel via a conveyor system, which comprises two distinct zones: a washing zone and a rinsing zone.

Within the high-pressure washing zone, warm water is supplied under high pressure through nozzles, having been preheated to the desired temperature. Post-cleaning, the water flows through a filter screen back into the container and is then pumped back into the washing area after the container has been washed.

This washing machine operates on the principle of water recovery, significantly reducing water consumption for washing a single box. This method ensures efficient use of water by recycling it for further cleaning processes.

Design features of the machine include:

- Versatility adaptable to various container dimensions.

- Manufactured using stainless steel AISI 304.

- Conveyor speed adjustment capability (additional function).

- Automatic maintenance of the cleaning solution level in the tank.

- Filtration system for the cleaning solution, allowing reuse.

- Automatic maintenance of the cleaning solution’s temperature.

- Digital temperature control for precise adjustments of the cleaning solution.

- Automatic maintenance of the cleaning solution concentration (additional function).

- Water recirculation system.