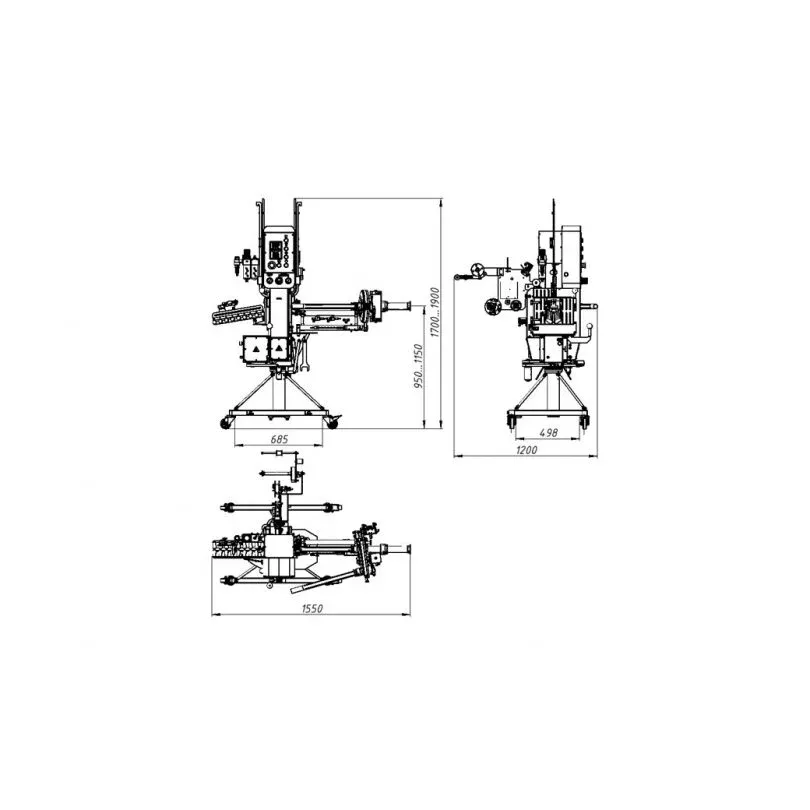

Fully Auto Double Clipper KOMPO KN-32 CHEESE MODEL

Fully Auto Double Clipper KOMPO KN-32 CHEESE MODEL

KN-32 CHEESE MODEL clippers represent the best combination of the operating speed and clipping quality. Clippers of this series are designed for working with various casings and are able to ensure a high operating speed along with the highest filling quality due to unique technologies used by KOMPO. The main advantages of KN-32 series clippers include economy, reliability, and compatibility with fillers of all major manufacturers. The high-quality materials used by KOMPO ensure a long service life with minimal wear on the machine and low maintenance costs.

KN-32 CHEESE MODEL clippers represent the best combination of the operating speed and clipping quality. Clippers of this series are designed for working with various casings and are able to ensure a high operating speed along with the highest filling quality due to unique technologies used by KOMPO. The main advantages of KN-32 series clippers include economy, reliability, and compatibility with fillers of all major manufacturers. The high-quality materials used by KOMPO ensure a long service life with minimal wear on the machine and low maintenance costs.

BENEFITS

- due to the central clamping device, the casing shift is reduced to zero;

- number of strokes – up to 60 portions per minute;

- casing reloading time reduced due to the two-spindle turret feeder with both manual and pneumatic rotation of the spindles;

- reconfiguration to various casing diameters without disconnecting the clipper from the filler;

- automation of all operations of the work cycle, including loop feeding for both sausages and sausage chains;

- possibility of combined operation with a dosing filler and dosing by the stick length;

- possibility of unitization with a filler of any manufacturer;

- regulating of sausage filling density;

- universality, simple maintenance, reliability and low operating costs.