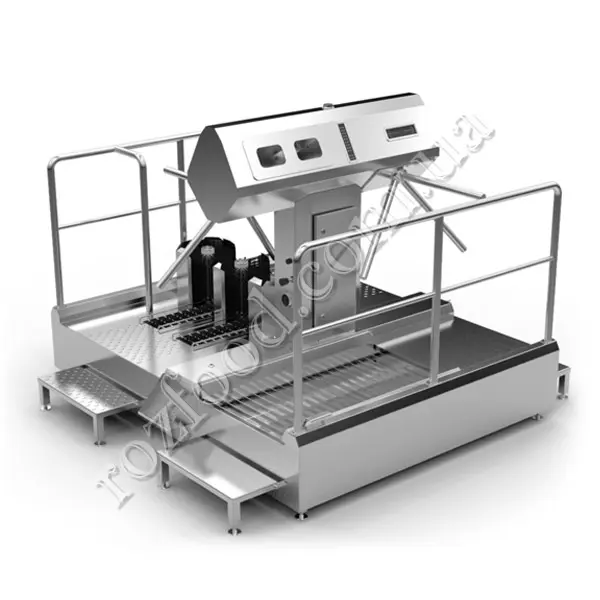

Máquina De Lavado De Canastas MMY 150

Máquina De Lavado De Canastas MMY 150

Lavadora de túnel KOMPO Boxes MMY-150 es una lavadora industrial de alto rendimiento para la limpieza automática de envases de plástico y metal. Sus chorros de alta presión y su avanzado sistema de filtración garantizan un lavado higiénico y sin residuos, cumpliendo con las normas de saneamiento de la industria alimentaria. Diseñada con acero inoxidable duradero, esta lavadora de túnel ofrece una limpieza eficiente y ecológica con un mínimo desperdicio de agua. Ideal para instalaciones de procesamiento y envasado de alimentos en México, Colombia y otros países de América Latina, aumenta la productividad al tiempo que reduce los costes operativos.

En KOMPO North America Inc. encontrará una amplia gama de lavadoras de estaciones higiénicas para empresas en México, Colombia y otros países de América Latina. Nuestro catálogo de productos también incluye una amplia gama de equipos para las industrias cárnica, láctea, panadera, de alimentos para mascotas y otras. Además de materiales fungibles de alta calidad para productores de salchichas y otros que necesitan grapas, tripas, lazos, bolsas retráctiles y mucho más.

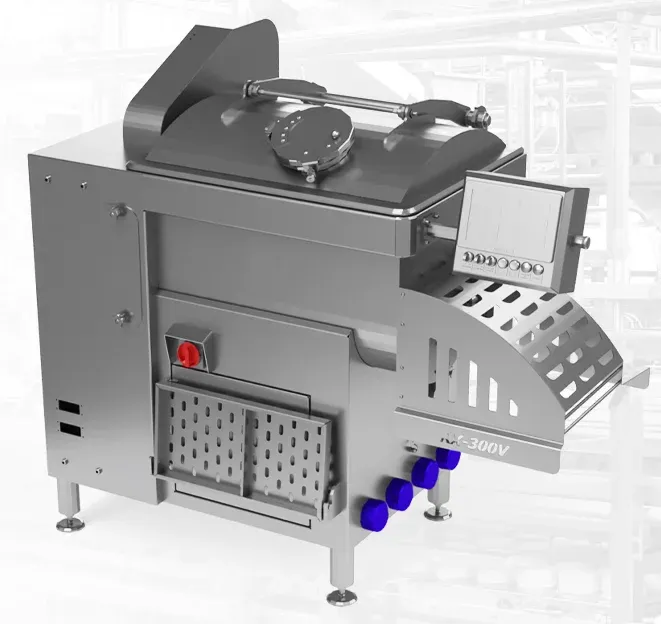

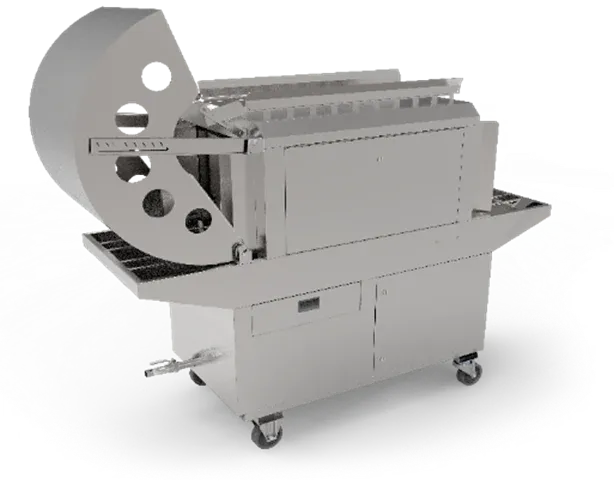

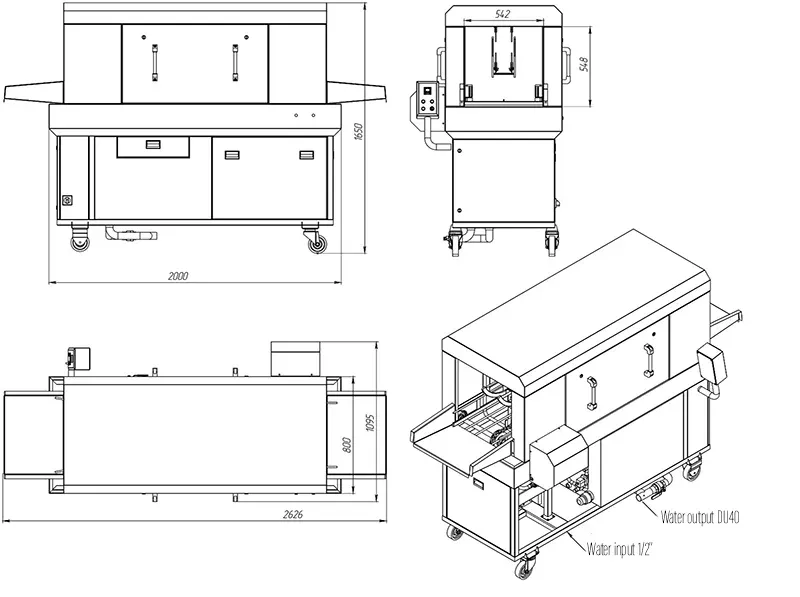

The Tunnel-type box washing machine MMY 150 is a versatile industrial washer designed to clean industrial boxes of E1, E2, and E3 types. It can also be adapted to wash bread trays, plastic trays, or boxes for transporting live birds. Containers to be washed are conveyed through the tunnel via a conveyor system, which comprises two distinct zones: a washing zone and a rinsing zone.

Within the high-pressure washing zone, warm water is supplied under high pressure through nozzles, having been preheated to the desired temperature. Post-cleaning, the water flows through a filter screen back into the container and is then pumped back into the washing area after the container has been washed.

This washing machine operates on the principle of water recovery, significantly reducing water consumption for washing a single box. This method ensures efficient use of water by recycling it for further cleaning processes.

The design features of the machine include:

- Versatility adaptable to various container dimensions.

- Manufactured using stainless steel AISI 304.

- Conveyor speed adjustment capability (additional function).

- Automatic maintenance of the cleaning solution level in the tank.

- Filtration system for the cleaning solution, allowing reuse.

- Automatic maintenance of the cleaning solution’s temperature.

- Digital temperature control for precise adjustments of the cleaning solution.

- Automatic maintenance of the cleaning solution concentration (additional function).

- Water recirculation system.

BENEFITS

- Programmable touch screen display

- One operator boxes return system (optional)

- Movable washing machine on wheels (optional)

- Rotational filter (optional)

- Powerful water pump

- Adjustable water consumption

- Adjustable water temperature

- Adjustable high and low pressure nozzles

- Adjustable conveyor speed

- Automatic washing soap dosing pump

- Custom made machines available