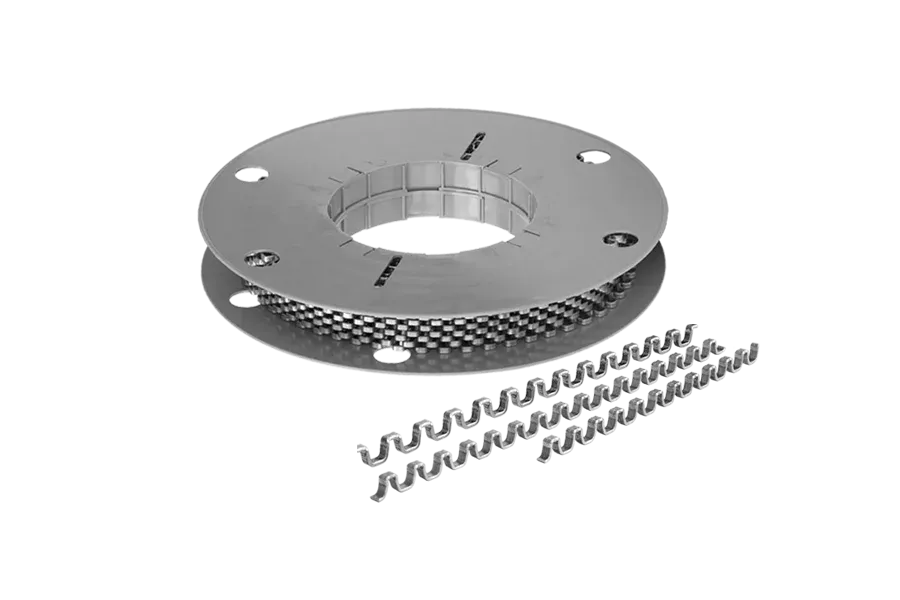

Collagen Casing PCS

Collagen Casing PCS

Collagen Casing PCS are made from livestock skins and tendons as raw materials. This casings are used for: Cooked sausages; Smoked sausages; Western sausages

Uniformity

Collagen casing PCS are made in a controlled industrial process, which means they have a uniform thickness and are stronger than natural casings. This can help ensure the consistency of the final product and make the production process more efficient.

Hygiene

Collagen casing PCS are made from hygienic materials and are sterilized during the production process, which can help reduce the risk of bacterial contamination.

Easy Handling

Collagen casing PCS are easier to handle than natural casings, as they are less fragile and more resistant. This can make the filling process faster and more efficient.

Conservation

Collagen casing PCS are individually packaged and vacuum sealed, which helps extend their shelf life and reduce waste.

Shelf Life

The shelf life is 3 years under the condition of the above transportation and storage conditions and its original package.

QUALITY FEATURES

- Good moisture and air permeability.

- High strength and elasticity.

- Stable caliber for quantitative stuffing.

- Fit for high speed stuffing machine.

- Good combination with stuffing.

- Thin texture and strong adhesion.

- Good flexibility, hard to break.

- Good mechanical properties, fit for high-speed stuffing.