High Speed Fully Auto Double Clipper KOMPO-SPRINT KN-501 cheese model

High Speed Fully Auto Double Clipper KOMPO-SPRINT KN-501 cheese model

KOMPO Sprint KN-501 cheese model is a high-speed, fully automatic double clipper designed for efficient cheese packaging in cheese factories and milk processors. It easily integrates with vacuum syringes to ensure reliable and leak-proof packaging of processed and soft cheeses. Made from stainless steel, this hygienic and durable machine meets the strict standards of the food industry. Ideal for cheese processing plants in Canada and the US, it provides speed, accuracy and cost efficiency.

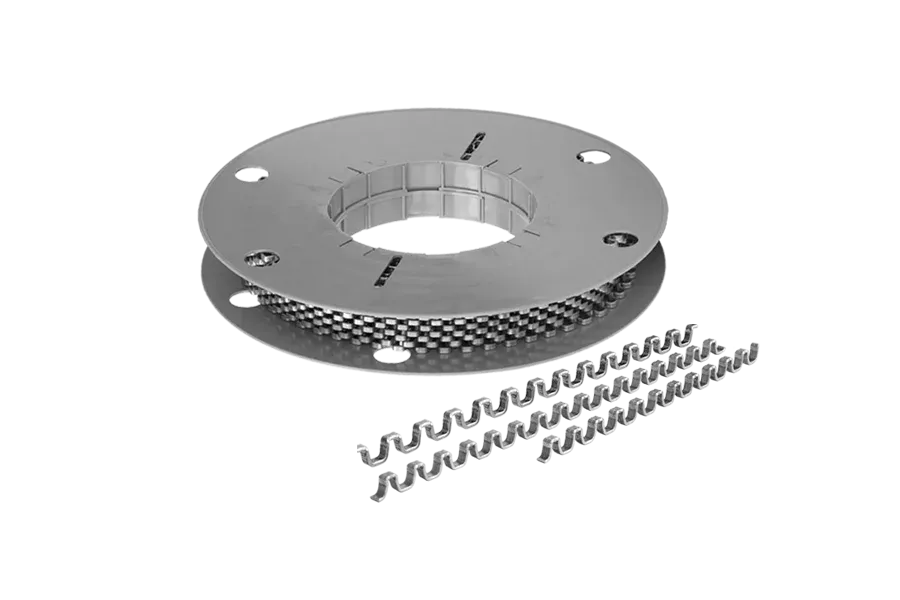

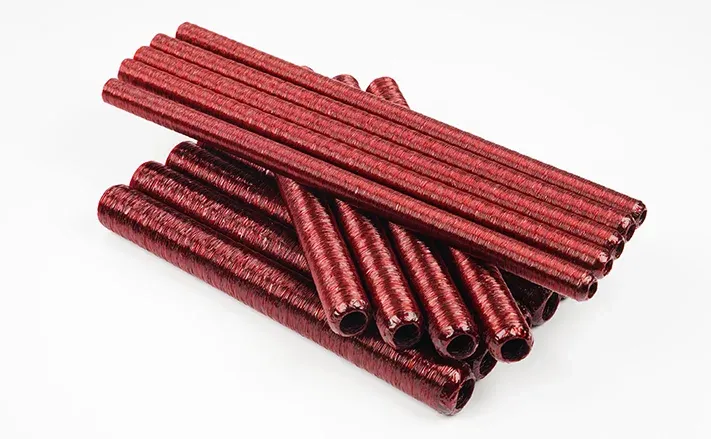

We also have a wide selection of consumables for this clipper, and in general for all clippers. If you need loops, clips, casings or any other consumables at the best prices on the market in Canada and the USA, you can contact us.

KOMPO Sprint KN-501 Cheese Model is a high-speed, fully automatic double clipper designed for sealing in cheese production in Canada or the USA. This state-of-the-art clipping machine easily integrates into the production chain and integrates with vacuum fillers to provide efficient and reliable sealing of processed cheeses, soft cheeses and other dairy products. Made of stainless steel, it meets the highest standards of hygiene and durability, making it ideal for industrial cheese processing in Canada and the USA.

Advantages:

- Maximizes productivity: High-speed automation increases throughput and efficiency.

- Reliable sealing: Provides tamper-proof, airtight packaging of cheese, extending shelf life.

- Reduced labor: Automation minimizes manual operations, increasing operational savings.

- Reliable and hygienic: Designed to ensure strict food safety in cheese processing plants.

- Versatile: Suitable for a variety of cheese packaging formats for adaptability.