Inwestpol Injector ANS-54

Inwestpol Injector ANS-54

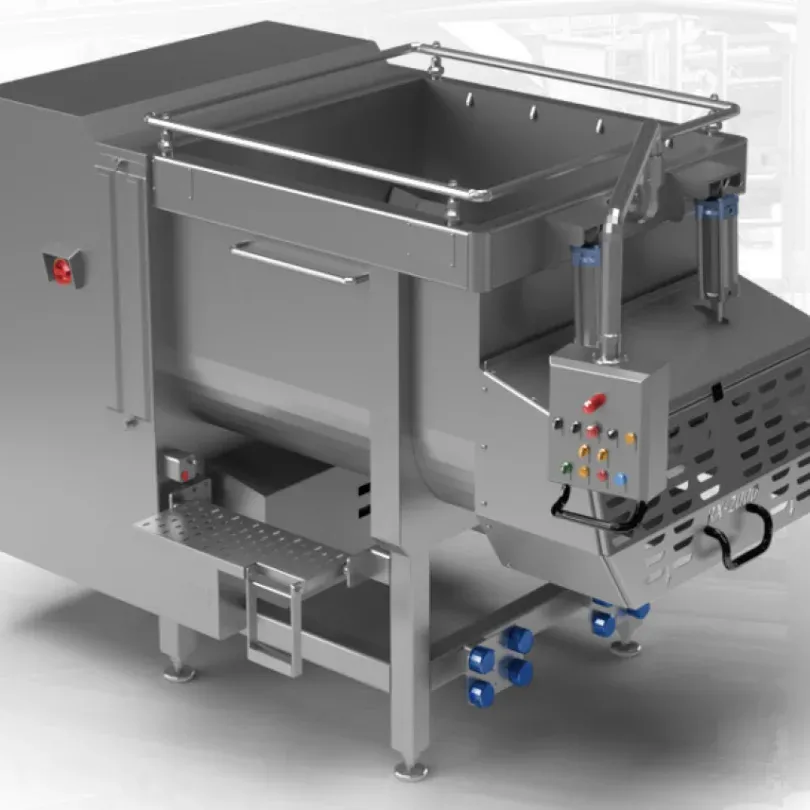

KOMPO ANS-54 Brine Injector is engineered for reliable, uniform brine injection in meat, poultry, and fish processing. With 54 injection needles, this model delivers high-throughput performance while ensuring even distribution of brine or marinade. Designed for food processors aiming to optimize yield, taste, and texture, the ANS-54 combines automation with hygienic construction to meet the demands of modern meat and poultry production environments.

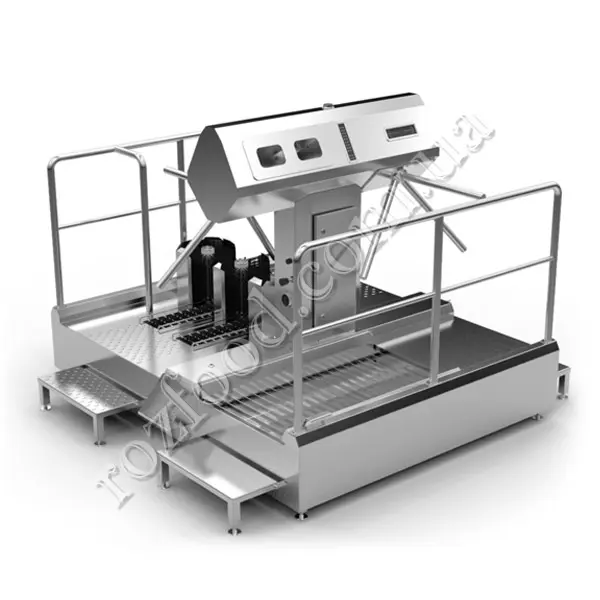

At KOMPO North America Inc. you will find a wide range of washers and hygienic stations for businesses in Canada and the USA. Our catalogue also includes a wide range of equipment for meat, dairy, bakery, pet food and other industries. As well as high quality consumables for sausage producers and others who need clips, casings, loops, shrink bags and much more.

Injector ANS-54 is a device to inject brine through a needle into meat. It can be used for injecting various types of meat: poultry, pork and beef, with and without bones. The device belongs to a new generation of machines that are equipped with Mitsubishi servomotor drive which allows to do accurate repeatable injections. Processor with touch panel gives the ability to program the following parameters:

- height of needles lifting and lowering;

- speed of the needle;

- system of the needle puncture;

- transport belt jump;

- pressure;

- moment of the injection.

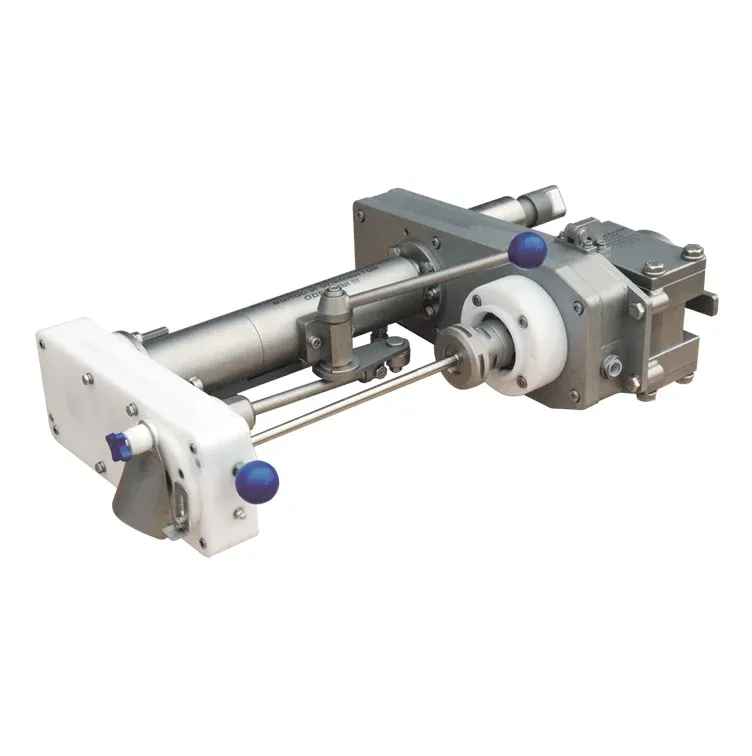

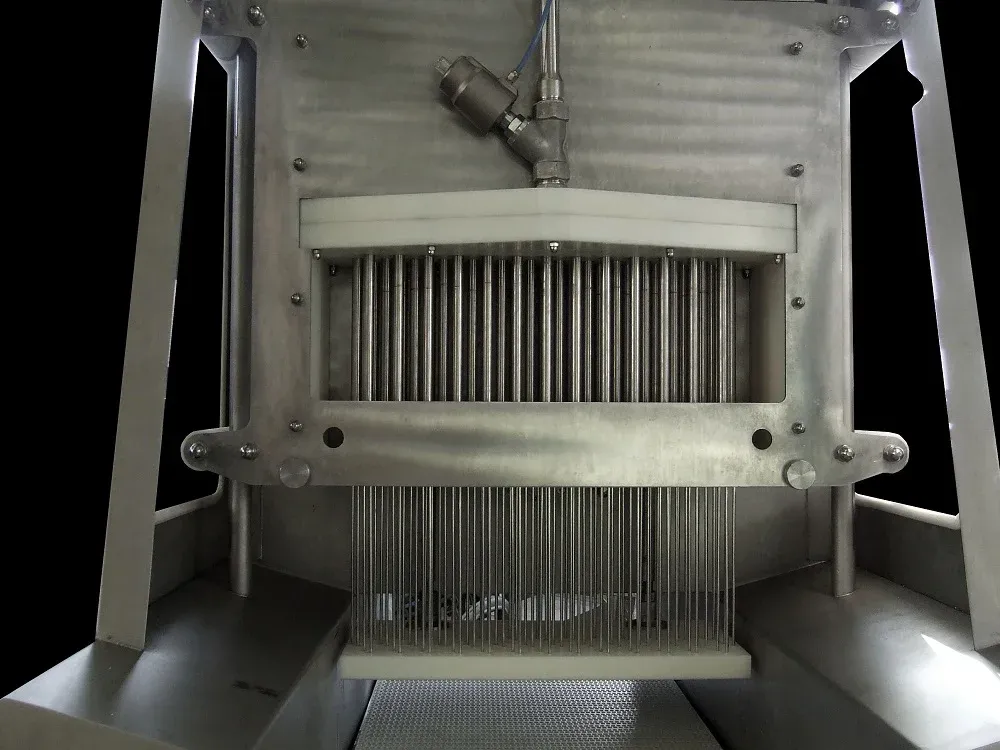

Needle block is sealed without flexible hoses. Needles and pressure plate are pneumatically amortized, brine supply valve is pneumatically opened, and the actuator is positioned over the conveyor belt, which prevents flooding and heating of the meat piece. The machine is equipped with a centrifugal stainless steel pump with smooth performance control. The Injector is designed to work with a rotating filter. Also, it would be equipped with a brine preparation station.

Stainless acid-proof steel construction

- New generation of injectors suitable for accurate and repeatable injection into poultry and red meat

- Servo drive Mitsubishi is independent for conveyor belt and for needle plate, over the conveyor trough – it prevents from brine flood and from warming up of the tools

- Closed, without flexible pipes needle block

- Pneumatic amortization of needles and plate is adjustable on the control panel

- The pneumatically openable valve which supplies brine to the needles

- Stainless steel centrifugal pump with fluent regulation of effectiveness

- The following parameters can be adjusted on Mitsubishi touchscreen control panel: Height of needle lift up and down; Needle speed; Single, double and triple injecting during one conveyor belt shift; Pump effectiveness 0 -100%; All parameters can be adjusted during the machine in process without interruption

- The injector is adapted to work with a rotary gap filter