N&N Nadratowski Cooking mixers MIX COOK SERIES

N&N Nadratowski Cooking mixers MIX COOK SERIES

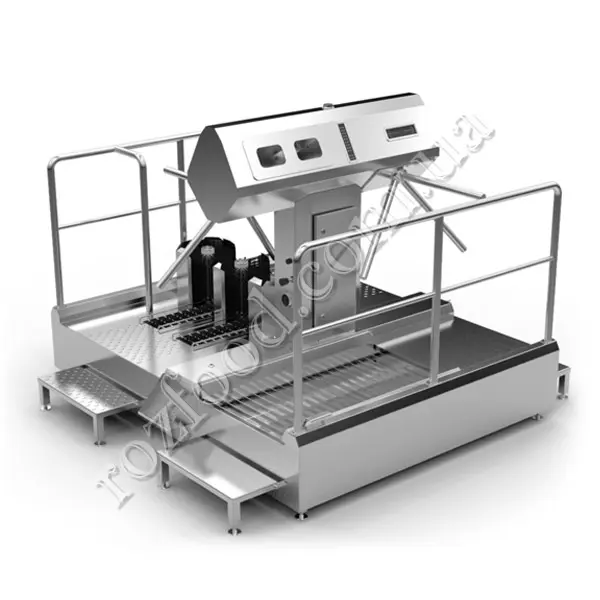

MIX-COOK Series by N&N Nadratowski offers advanced cooking mixers engineered for simultaneous mixing, cooking, and cooling of a wide range of food products. Designed for high-efficiency thermal processing, these machines are ideal for ready meals, sauces, fillings, pet food, plant-based products, and more. Each unit features precise temperature control, automated mixing programs, and vacuum or pressure cooking options, ensuring consistent product quality and reduced cooking times. Constructed from high-quality stainless steel, the MIX-COOK mixers are easy to clean and fully compliant with food industry hygiene standards. KOMPO North America Inc. supplies these cooking mixers across Canada and the USA, ensuring local support and service for industrial food processors.

At KOMPO North America Inc. you will find a wide range of washers and hygienic stations for businesses in Canada and the USA. Our catalogue also includes a wide range of equipment for meat, dairy, bakery, pet food and other industries. As well as high quality consumables for sausage producers and others who need clips, casings, loops, shrink bags and much more.

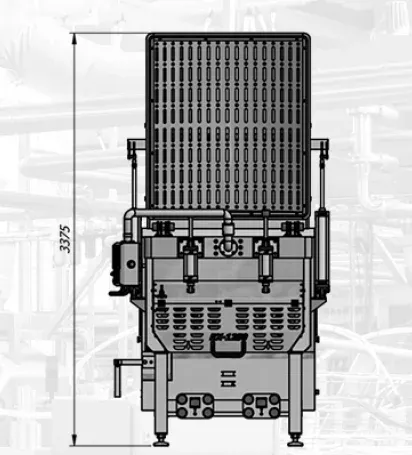

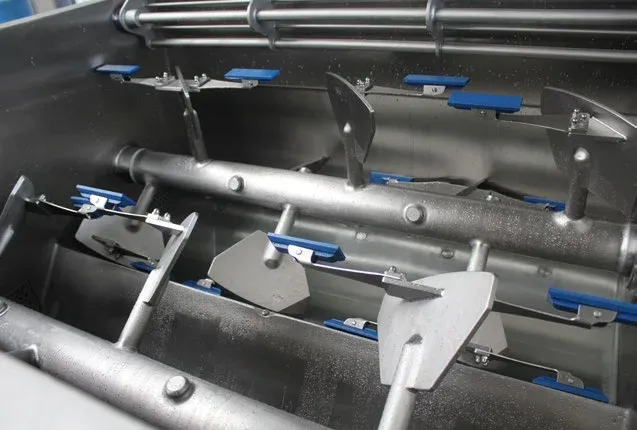

PARALLEL TWIN SHAFTS

In the MIX Cook series mixers, the mixing process is carried out by two twin parallel paddle or ribbon shafts, placed at the same heights. Characteristic feature of this series of machines is the possibility to set the speed and direction of rotation independently for each shaft.

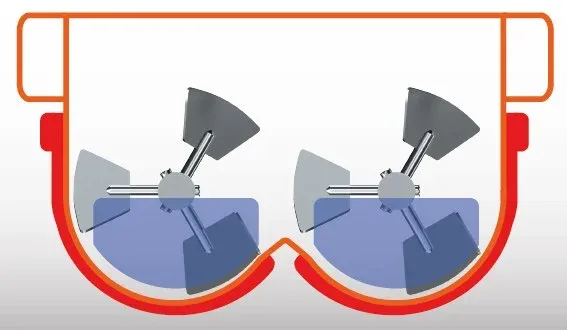

UNLOADING

N&N’s mixers of the MIX Cook series, thanks to the two built-in discharge flaps and low clearance between the shaft s and the mixing bowl, enable fast and safe ejection of the cooked product, while leaving only minimal amount of product between the individual batches.

CONTROL

MIX Cook series mixers are equipped as standard with a colour HMI touch screen, which is user-friendly and intuitive to use. Dedicated software with advanced cooking options and process monitoring and control equipment allows you to maximize product efficiency. Possibility of recipe management and access control allows to maintain repeatability of individual product batches.

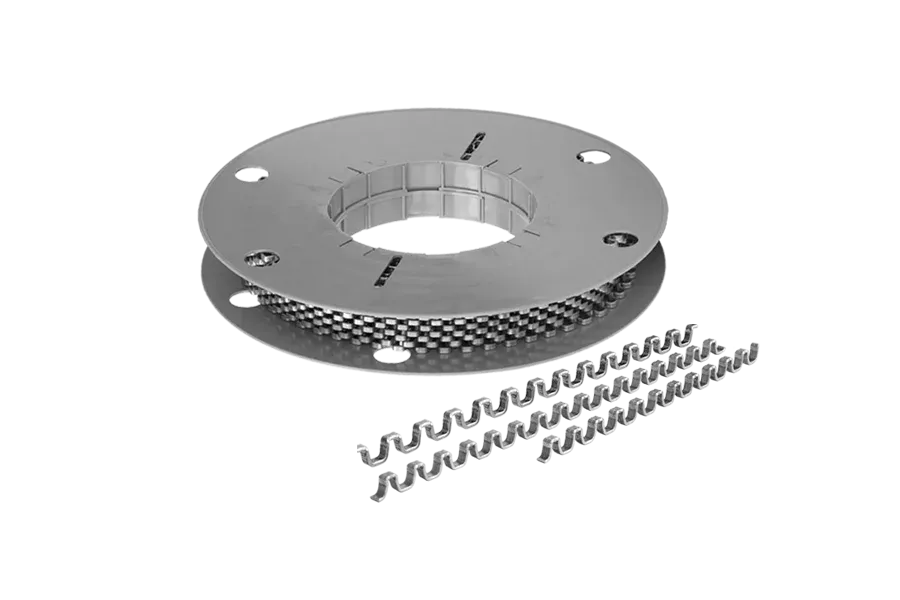

SCRAPERS

MIX Cook series mixers can be optionally equipped with an innovative system of scrapers consisting of a springy claw and a special high-temperature-resistant plastic, which perfectly scrape the product from the whole heating surface of the jacket and prevent the product from burning.

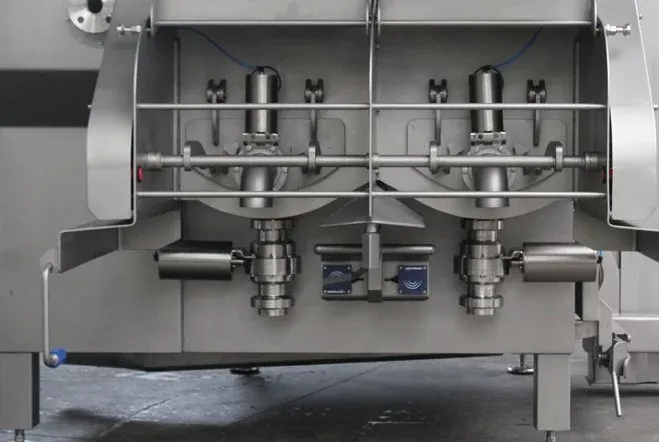

DIRECT STEAM INJECTION

All MIX Cook series machines can be equipped with a system of hygienic nozzles for direct steam injection into the product, which can accelerate the process even several times without the effect of burning.

Key Features:

- Integrated Cooking, Mixing, and Cooling Functions

- Vacuum and Pressure Cooking Options

- PLC-Controlled with Programmable Recipes

- Highly Efficient Thermal Transfer for Faster Processing

- Durable Stainless Steel Construction with Easy Clean Design